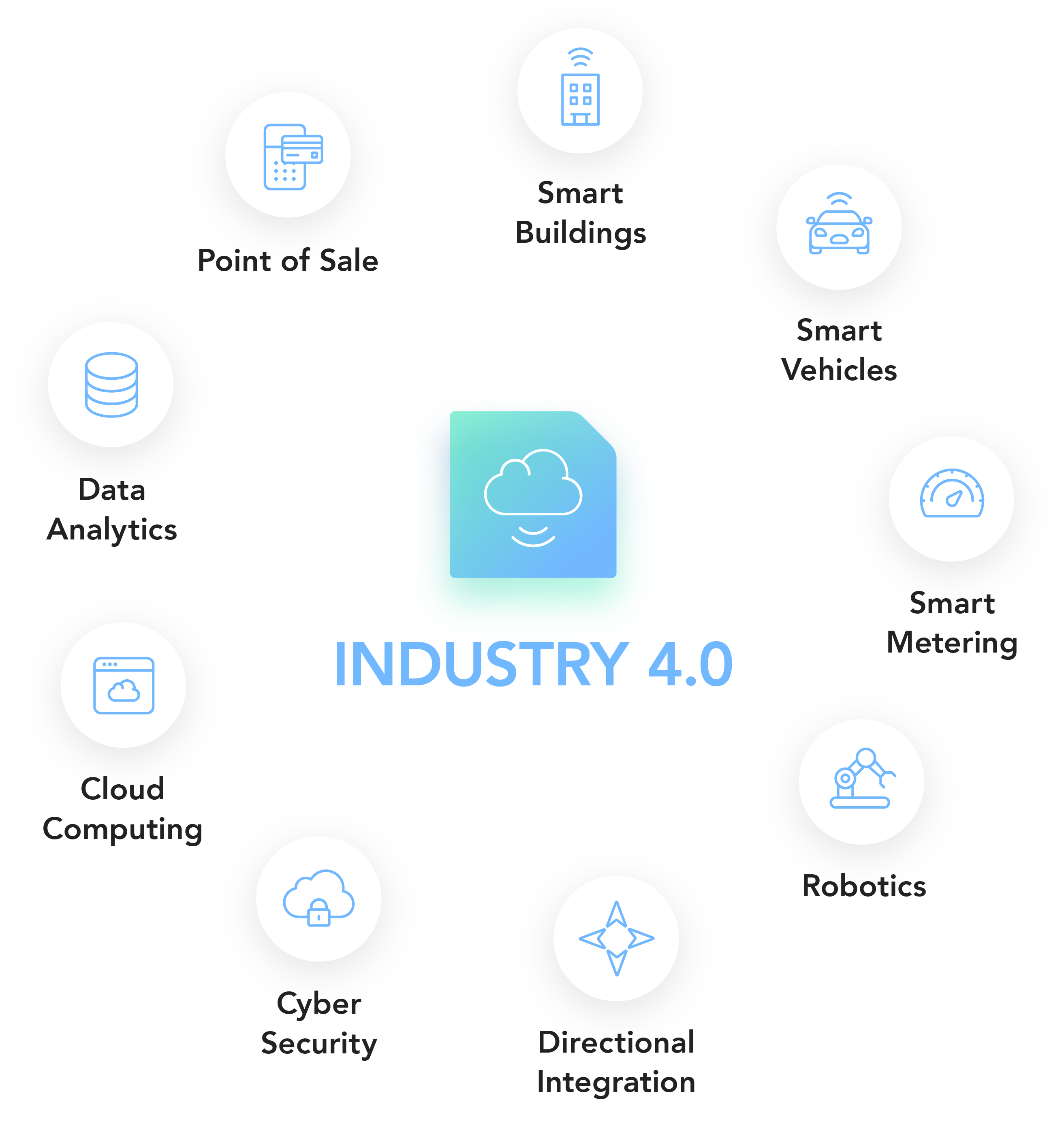

Industry 4.0 is a term for the fourth industrial revolution: the digitization and automation of manufacturing. We are in the midst of a fundamental shift in the way products are produced, and it’s deeply tied to the future of the Internet of Things (IoT).

Advances in networking, machine learning, data analytics, robotics, 3D printing, and other technologies are making vast improvements on industrial processes and reducing our dependence on human labor and decision-making. By leaning into digital solutions, manufacturing can reduce human error, shorten time to market, and increase the speed at which industrial processes can adapt to new information.

Leveraging the Industrial Internet of Things (IIoT), Cyber Physical Systems, and Internet of Services, “Smart Factories” can help operators make data-driven decisions or even autonomously trigger actions. Machine-to-Machine communication allows these factories to track products with pinpoint accuracy as they pass through the facility, using sensors to record progress and collect valuable information.

Coupled with new infrastructure, Smart Factories can mass produce products while remaining agile enough to profitably create small-batch products based on individual customer requirements. They’re also capable of dynamically reacting to unforeseen challenges that could significantly disrupt manufacturing operations—such as a last-minute change in suppliers.

In this guide, we’ll explore the design principles driving Industry 4.0 and some of the main concepts you need to be familiar with in this rapidly evolving space.

But first, let’s talk about how this all began. When did the fourth industrial revolution start, and why is it called Industry 4.0?

Where did “Industry 4.0” come from?

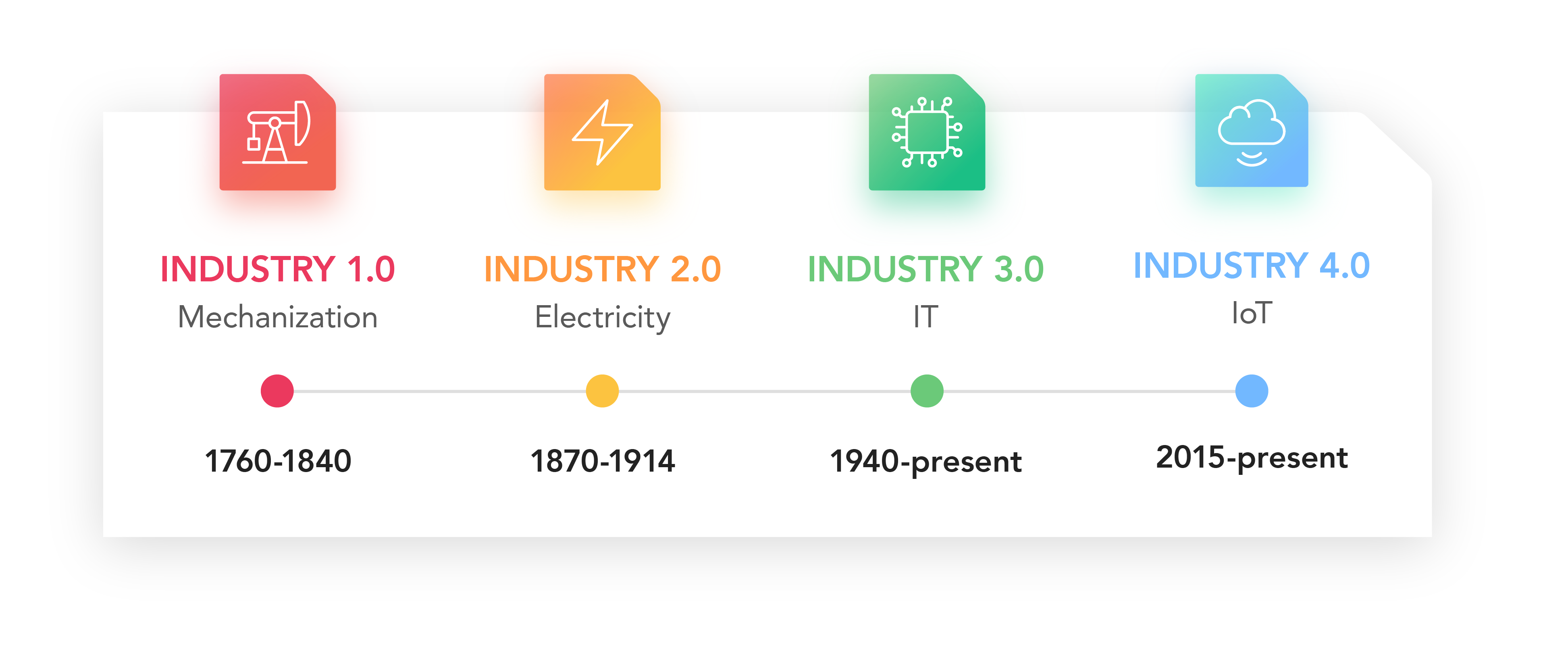

The term “Industrie 4.0” originated within the German government. Introduced in 2011, it represented the growing body of research and development regarding the computerization of manufacturing.

A collective of German researchers formed to explore the state of manufacturing and establish Germany’s place within it. Known as the Industrie 4.0 Working Group, they produced a list of recommendations for the government in 2012, then presented it at the Hannover Fair in 2013. These recommendations outlined the research and development needed to successfully transition to Industry 4.0.

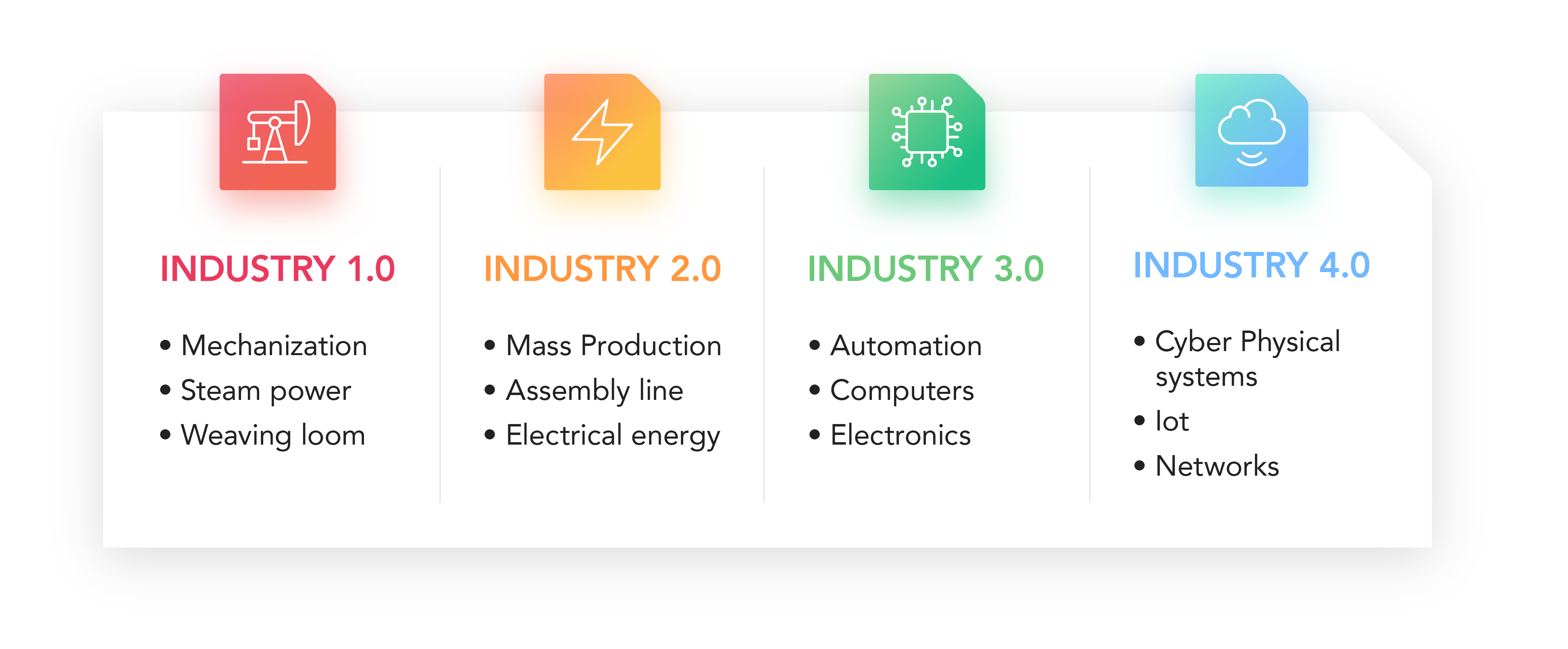

Introducing their list, the group noted, “The first three industrial revolutions came about as a result of mechanization, electricity and IT. Now, the introduction of the Internet of Things and Services into the manufacturing environment is ushering in a fourth industrial revolution.”

Since then, the term and the Industrie 4.0 Working Group’s recommendations have worked their way around the world, driving the future of manufacturing and sparking a new wave of academic discussion around the fourth industrial revolution.

By the time the Industrie 4.0 Working Group developed their recommendations, some Smart Factories were already embracing certain aspects of Industry 4.0. The world’s leading manufacturers have since been quick to invest in these technologies and implement changes to their infrastructure.

Still, despite its prominence in the manufacturing world, the global discussion around Industryie 4.0 often lacked consensus and cohesiveness. Using quantitative and qualitative analysis, a 2016 paper identified four key design principles inherent in Industry 4.0.

The four design principles of Industry 4.0

There are numerous branches of technology that make Industry 4.0 possible. But they all generally fall under four overarching principles:

- Interconnection

- Information transparency

- Technical assistance

- Decentralized decisions

Interconnection (or interoperability)

Machine-to-machine and machine-to-person communication is a crucial part of Industry 4.0. In order to make data-driven decisions and reduce our dependence on human labor, factories and industrial processes need rich integration between the hardware and software involved in production.

The Internet of Things makes this principle of interconnection possible. It enables manufacturers to collect information from their machinery and equipment and access it in useful ways through a database. Thanks to advances in networking technology (particularly in cellular IoT), it’s possible to connect thousands of devices in a concentrated area and maintain reliable coverage indoors.

This goes beyond Internet-enabling machines. These hardware and software components need to be integrated in meaningful ways so that they can share data. Operators shouldn’t need to switch between dozens of applications to manage the production line and analyze their data. Industry 4.0 technology needs simple APIs to facilitate true interoperability.

Information transparency

Traditional manufacturing is held back by a lack of visibility into production. Humans have to relay information and manually provide status updates. But along the production line and throughout the lifecycle of the product, there are countless blindspots where operators simply don’t have the data they need to make improvements and optimize processes.

Industry 4.0’s interconnectedness opens the door to information transparency, enabling manufacturers to collect vast amounts of data at every step of production. Using this aggregate information, operators can see problems, inefficiencies, and opportunities that simply weren’t visible before.

Additionally, when building IoT devices, manufacturers can continue collecting data after the product leaves the factory, improving their ability to optimize, adapt, and correct products.

Technical assistance

Humans are fallible. And even with access to the right data, we can still make poor decisions or misinterpret the data. Machine learning enables devices and applications to scan and evaluate data far more rapidly and accurately than humans.

For complex processes that still require human decision-making, Industry 4.0 creates pathways for technology to assist, providing alerts and notifications to identify failures, drops in quality, or weaknesses in the production cycle. Technology like augmented reality and cloud computing also allows organizations to create simulations and test environments, so they can identify problems before they become costly mistakes, and develop solutions that they can deploy with confidence.

Industrial technology can also support humans with tasks that are difficult or unsafe. For example, maintenance is vital for keeping performance consistent and maximizing the lifespan of equipment. But traditionally, maintenance is more of a reactive process. Part of Industry 4.0 is shifting to predictive maintenance.

Humans can manually collect information and recognize maintenance needs periodically, but it can be difficult to identify problems until something breaks or fails, resulting in unscheduled downtime. Industrial IoT, Big Data, and machine learning enable devices and applications to recognize when maintenance is needed before a failure occurs, giving operators time to schedule repairs and plan around them.

Industrial enterprises have continually strived to create safer work environments for their employees, but there are still many dangerous tasks that humans simply have to do. Industry 4.0 is changing that, using robotics to assist humans with tasks involving harsh chemicals, molten materials, tight spaces, heavy lifting, and other hazardous conditions.

Decentralized decisions

Beyond simply assisting humans with decisions, Industry 4.0 also enables machinery to make simple, routine decisions autonomously.

In manufacturing, relying too heavily on manual decision making creates a bottleneck: everything has to be routed through an employee, and they can only make one decision at a time. If humans rush these decisions, it may increase the error rate. Machines empowered by artificial intelligence can recognize patterns and be configured to react to data with the same choices a human would make.

This frees employees to focus on the situations that truly require their attention, only elevating decisions to humans when there are conflicting goals, unusual circumstances, or some form of interference.

Key concepts of Industry 4.0

The challenge with defining Industry 4.0 is that it encompasses such a broad array of technologies. To understand what makes the fourth industrial revolution a revolution, you have to recognize the distinct qualities that these various concepts bring to manufacturing and how, together, they completely change the way we produce goods.

Here are some of the core concepts and technologies that fulfill the design principles of Industry 4.0.

Internet of Things (IoT)

As discussed above, networking devices and retrieving data from equipment is a foundational part of Industry 4.0. IoT isn’t new, but it is rapidly expanding. Advances in cellular technology like 5G and specialized IoT networks like LTE-M and NB-IoT are opening the door to new cellular capabilities and making more efficient use of the Radio Frequency spectrum—so we can concentrate more devices in the same space, and build applications that solve more complex problems.

Cyber Physical Systems (CPS)

Cyber Physical Systems tie together robotics, IoT, and machine learning. A CPS is essentially any mechanical process that is automatically controlled by software. Using sensors and other inputs from the mechanical components, the software runs algorithms that determine how it should control the machinery, equipment, or infrastructure.

A CPS can react to changes in its environment and operate in different spaces and configurations, making it easy to adapt to a manufacturer’s changing needs.

Big Data analytics

“Big Data” refers to data sets that are exceptionally large or complex, making them difficult to process in a timely manner—even with software. A single IoT device can produce enormous quantities of data to analyze. When you have tens of thousands of interconnected devices, the challenge is to find the most valuable ways to collect, store, analyze, and use that data.

In Industry 4.0, wrestling with Big Data is the key to implementing predictive maintenance and understanding user behavior. Manufacturers have to develop systems for efficiently isolating valuable information and managing their vast quantities of aggregate data.

Horizontal and vertical systems integration

In Industry 4.0, every company, process, employee, department, and piece of equipment involved in manufacturing needs to communicate. From research and development, to the supply chain, to the production floor, to customer service, to marketing, and to sales, there needs to be transparency and coordination.

Horizontal systems integration in Industry 4.0 refers to the integration of the various software and hardware used in production. Regardless of how many different vendors the equipment and applications came from, it should work together seamlessly and intelligently. This enables Smart Factories to respond dynamically to new production requirements and helps facilitate predictive maintenance.

For manufacturers with multiple facilities, horizontal systems integration also involves coordinating production between them. When these systems are connected, the enterprise can use production resources more efficiently by automatically adjusting to delays, changes in the supply chain, and other variables that could impact each facility differently.

Vertical systems integration in Industry 4.0 refers to the integration of a manufacturer’s various departments, from production to IT to quality assurance and sales. Rather than siloing data and making decisions based on limited data, each layer of the business can access relevant information from the others. This helps ensure that decisions are always informed by data and made with an understanding of how it could impact other aspects of the business.

Cloud computing

Cloud computing makes IT resources like data storage and computing power available on demand. Cloud service providers use one of three cloud computing models:

- Software as a Service (SaaS): The customer pays a provider to use cloud-based software

- Platform as a Service (PaaS): The customer pays a provider for the IT resources and infrastructure they need to develop, operate, and manage their own application

- Infrastructure as a Service (IaaS): The customer pays a provider for the servers, storage, and datacenters they need to facilitate their own platform.

Cloud computing enables manufacturers to quickly scale their IT infrastructure up and down by paying for the resources they need, when they need them. This allows them to do things like create temporary test environments and keep IT resources local to customers when they deploy IoT devices in countries where they don’t already have infrastructure in place.

Additive manufacturing

Additive manufacturing is part of what enables manufacturers to rapidly produce small batches of products based on individual customer specifications. Using 3D printing and digital modeling, factories can profitably create one-off products. Since these products are created layer-by-layer, this process uses materials more efficiently, and the time to market is extraordinarily short.

Become part of the fourth industrial revolution

EMnify is a cloud communication platform dedicated for IoT. Our specialized IoT SIM cards enable your devices to connect to more than 540 networks in over 180 countries, so you can deploy anywhere in the world. Our intuitive portal and dashboard gives you complete control over your connectivity so you operate any number of deployments efficiently. With a comprehensive security approach we ensure that your manufacturing and monitoring devices cannot be misused-

As with all true Industry 4.0 technology, our platform can fully integrate with your OSS and BSS tools. Our REST API brings all the connectivity data you need to the platforms you already use.

Whatever your application, we have the cellular components and connectivity solutions you need.

Get in touch with our IoT experts

Discover how emnify can help you grow your business and talk to one of our IoT consultants today!

emnify

The content team of emnify is specialized in all things IoT. Feel free to reach out to us if you have any question.